Discover More

Discover More

Discover More

Discover More

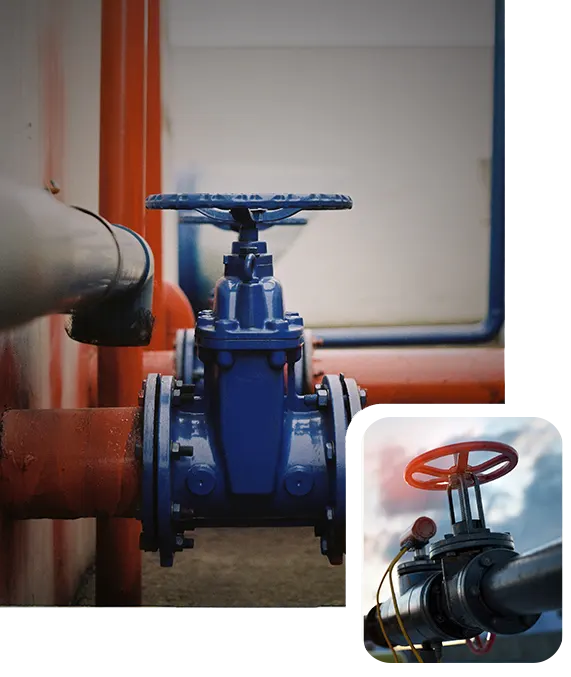

We produce and market all types of flow control products

VINFLOW management always keeps the focused vision and follows a total quality approach to develop and offer the products conforming to highest international standards.

- Gate Valves (Metal Seated, Resilient Seated, Knife)

- Globe valves

- Swing Check Valves

- Butterfly valves

- Ball Valves

- Air Valves

- Y-Strainers

- Hydraulic Control valves

Variety of Industries

Variety of IndustriesOur valves cater to a wide variety of industries and a few of them have been provided below.

- Potable Water, Water purification & Sewage

- Petroleum, Oil & Gas

- Petrochemical & Process Industries

- HVAC & Cooling Water

- Edible Oil & Food Processing

- Power Plants

- Variety of other allied industries

Our Products

Pneumatic Actuator

Pneumatic Actuator

Pneumatic Actuator

We offer a range of pneumatic actuators designed for reliable and efficient valve automation. Our product lineup includes both Double Acting Pneumatic Actuators and Single Acting Pneumatic Actuators, providing flexibility to suit various application requirements.

Key Features:

- Double Acting Pneumatic Actuator: (DA series)

-

- Enables both opening and closing actions.

- Smooth and reliable operation.

- Available in multiple sizes to match valve requirements.

- Body material: Aluminum Alloy.

- Conforms to ISO5211 and NUMAR connection standards.

- Zero leakage allowed.

- Ideal for quarter turn valve applications.

- Single Acting Pneumatic Actuator: (SR series)

-

- Designed for spring return operation.

- Provides reliable performance with quick reaction.

- Available in multiple sizes to match valve requirements.

- Body material: Aluminum Alloy.

- Conforms to ISO5211 and NUMAR connection standards.

- Zero leakage allowed.

- Ideal for quarter turn valve applications.

Both types of actuators are constructed with high-quality materials and offer excellent performance, ensuring safe and efficient valve automation. Our pneumatic actuators are suitable for a wide range of industries, including oil refining, chemical processing, and more.

Contact us to find the perfect pneumatic actuator solution for your valve automation needs.

- client: Dr. Devis

- Location: USA

- Surface Area: 75,020 m

- Architect: Alex Hales

- Year Of Complited: 2017

- Project Value: $950000

Electric Actuator

Electric Actuator

Electric Actuator

The VINOM series quarter turn electric valve actuators offer a torque range of 35 Nm to 4500 Nm. These actuators are chosen by users based on their specific load requirements. They employ planetary gearing with self-locking, ensuring stable and reliable operation by preventing valves from being back driven. The actuators feature an ISO 5211 Flange connection for easy mounting to valves, and a raised mechanical position indicator allows operators to identify the valve position. Notably, these actuators have a clutch-less manual override design, eliminating the need for a clutch or brake when switching from electrical to manual operation. This design enhances ease of operation, increases mechanical reliability, and reduces failure rates.

- client: Dr. Devis

- Location: USA

- Surface Area: 75,020 m

- Architect: Alex Hales

- Year Of Complited: 2017

- Project Value: $950000

BASKET STRAINER

BASKET STRAINER

BASKET STRAINER

Our Basket Strainer with SS316 Screen is designed to provide efficient and reliable filtration for various fluid handling systems. It combines the strength and durability of ductile iron with the corrosion resistance of stainless steel, making it an excellent choice for demanding applications.

Key Features:

- Ductile iron body for strength and durability.

- SS316 stainless steel screen for excellent corrosion resistance.

- Suitable for a wide range of applications, including water, oil, gas, and chemical processes.

- Robust construction for long-lasting performance.

- Easy installation and maintenance.

- Removable basket with SS316 screen for convenient cleaning and maintenance.

- Available in various sizes and pressure ratings.

- Optional features such as pressure gauges, drain valves, and differential pressure indicators.

- Provides reliable removal of debris, solids, and contaminants to protect downstream equipment.

- Ensures uninterrupted flow and minimizes system downtime.

Our Ductile Iron Basket Strainer with SS316 Screen is designed to deliver efficient filtration and system protection in demanding environments. Contact us to learn more about its features and how it can enhance the performance of your fluid handling system.

| Model | VIN-BST |

| Type | BASKET TYPE |

| Diameter range | DN50 – DN600 |

| Maximum operating pressure | 16 Bar / PN16 |

| Coating | 250 microns Epoxy Powder Coating |

| Flange Suitability | PN16 (other standards available on request) |

- client: Dr. Devis

- Location: USA

- Surface Area: 75,020 m

- Architect: Alex Hales

- Year Of Complited: 2017

- Project Value: $950000

Y-TYPE STRAINER

Y-TYPE STRAINER

Y-TYPE STRAINER

Our Y-type strainer is specifically designed for water applications, offering reliable protection for meters, pumps, valves, and other pipeline equipment. Equipped with a stainless-steel screen, it effectively filters out debris and particles, ensuring the smooth operation of your system.

Key Features:

- Y type strainer with stainless-steel screen.

- Ideal for water applications.

- Provides protection for meters, pumps, valves, and pipeline equipment.

- Efficiently filters out debris and particles.

- Ensures uninterrupted system operation.

- Robust construction for long-lasting performance.

- Easy to install and maintain.

- Suitable for a variety of pipeline sizes.

When it comes to safeguarding your water system, our Y type strainer is the perfect choice. Contact us to learn more about its features and how it can benefit your specific application.

|

Model |

VIN-YST |

|

Type |

Y-TYPE |

|

Diameter range |

DN15 – DN400 |

|

Maximum operating pressure |

16 Bar / PN16 |

|

Coating |

250 microns Epoxy Powder Coating |

|

Flange Suitability |

PN16 (other standards available on request) |

- client: Dr. Devis

- Location: USA

- Surface Area: 75,020 m

- Architect: Alex Hales

- Year Of Complited: 2017

- Project Value: $950000

SINGLE ORIFICE AIR VALVE – FLANGED

Wafer Type Butterfly Valve –

Gear Operated

WAFER TYPE BUTTERFLY VALVE – LEVER OPERATED

- The water butterfly valves are designed with different options for disc and seat materials to cater to diverse applications.

- Typical application includes HVAC, Petrochemical processing, oil & gas process, shipbuilding and offshore, firefighting and sanitary system, food industries, etc.

- These valves are equipped with a replaceable rubber liner that effectively isolates the valve body, providing optimal protection against corrosion.

|

Model |

VIN-WTL |

|

Diameter range |

DN50 – DN300 |

|

Maximum operating pressure |

16 bar / PN16 |

|

Coating |

300 microns FBE |

|

Flange Suitability |

PN10 / PN16 / ANSI 150# / JIS 10 K |

- client: Dr. Devis

- Location: USA

- Surface Area: 75,020 m

- Architect: Alex Hales

- Year Of Complited: 2017

- Project Value: $950000

SINGLE ORIFICE AIR VALVE – THREADED

SINGLE ORIFICE AIR VALVE – THREADED

SINGLE ORIFICE AIR VALVE – THREADED

Single Orifice Air Release Valve is designed to efficiently release air from fluid handling systems, ensuring optimal performance and preventing air accumulation. It is available with both threaded and flanged ends, providing flexibility for installation in various piping systems.

Key Features:

- Single orifice design for efficient air release.

- Available with threaded ends for easy installation or flanged ends for secure connection.

- Helps maintain system efficiency by releasing trapped air.

- Prevents air accumulation in fluid handling systems.

- Durable construction for long-lasting performance.

- Suitable for a wide range of applications.

- Helps reduce the risk of cavitation and system damage.

- Allows for smooth and uninterrupted flow.

- Easy to maintain and service.

Whether you prefer threaded ends or flanged ends, our Single Orifice Air Release Valve provides reliable air management in fluid handling systems. Contact us to learn more about its features and how it can improve the efficiency of your system.

|

Model |

VIN-AVS |

|

Type |

SINGLE ORIFICE |

|

Diameter range |

DN15 – DN200 (DN15-DN25 THREDED ENDS) (DN50-DN200 FLANGED ENDS) |

|

Maximum operating pressure |

16 Bar / PN16 |

|

Coating |

250 microns Epoxy Powder Coating |

|

Flange Suitability |

PN16 (other standards available on request) |

- client: Dr. Devis

- Location: USA

- Surface Area: 75,020 m

- Architect: Alex Hales

- Year Of Complited: 2017

- Project Value: $950000

We also have Electric, Electric Spring Return and Pneumatic actuators in our range of supply. Our valves and electric actuators are manufactured in facilities that have state of art technology by using high quality raw materials. We believe in accepting challenges by putting efforts in improving the infrastructure and developing high standard in-house inspection and testing facilities for ensure customer satisfaction.

Our Strengths are

Wide range of products and services

High Quality Products at nominal prices

Excellent delivery time

Client rating

5.00 Average Based On 50 Rating – More information

Contact Us for more product

Contact Us for more product

We seek to distinguish ourselves by providing the most possible flexibility and reliability in customer service by offering a range of solutions.